Marlin 1.1.9

Printrboard and Modern Marlin

Tested Release For Heated and Non-Heated Bed Models

Highlights

- This firmware upgrade increases print quality to a level comparable with Prusa Mk3 and Ultimaker 3 all thanks to Linear Advance v1.5 available starting with Marlin 1.1.9

- Babystepping allows live Z-offset during the start of the print

- Size optimized for 128k storage of AT90USB1286 processor

- 3 Point Leveling seems to work better for smaller beds

- Bilinear Bed Leveling which is useful for larger uneven beds

Selecting Firmware for your board

The firmware versioning scheme I used to track changes I made caused some confusion, so just to clarify. The firmware version number does not relate to the board version number. There are only two firmware versions that cover all board versions.

If your board is RevF0 - F6 then use RevF firmware. If your board is marked anything lower then RevF: Use Firmware Marked RevD, RevB

Example

Board Version|Firmware Version |Model |Build Size|Notes

RevF- 0.8_ PlayHB_200x100_Inverted_Probe

If you’re compiling your own firmare use these thermistor options

Hotend Thermistor - Ubis 13 (Ceramic Hotend) or Ubis 13s use: 1 EPCOS 100k

Heated Bed Thermistor table: 7

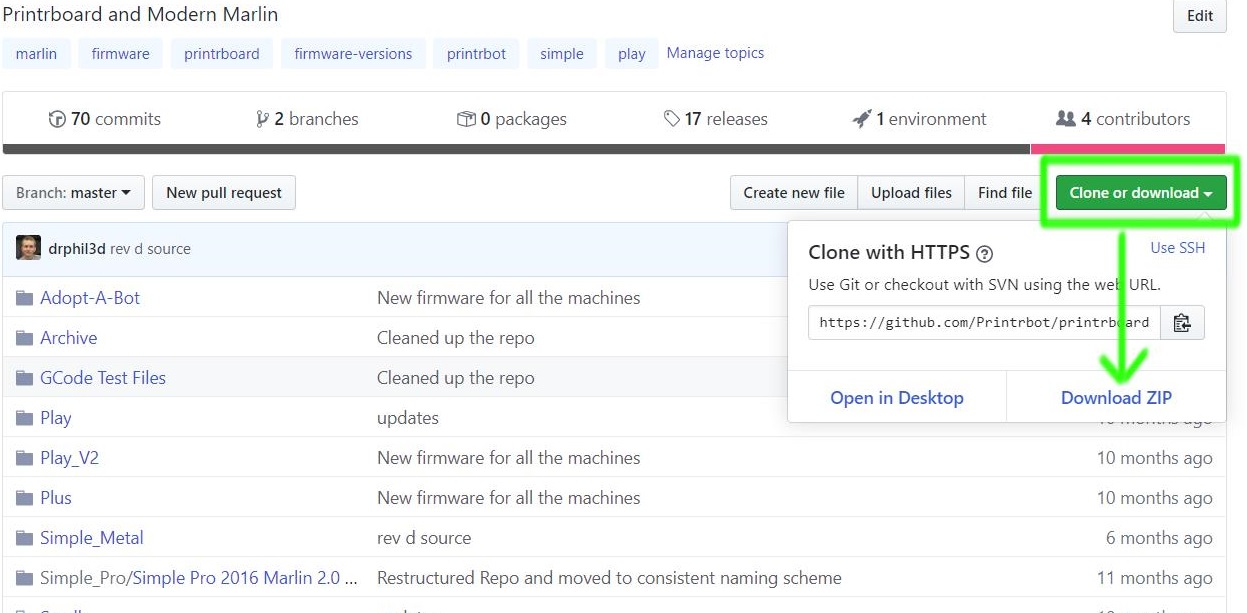

Downloading Firmware

Make sure to download repo as zip, otherwise right clicking and saving individual hex files will result in downloading an html file which will result in errors when flashing.

Change Log

v0.8 Added new machines, Neo Pixel, Added E3D Hotends, other small changes

v0.6 Smalls with Heated bed 200x150x150 no lcd

v0.5 bugs have been worked out for Play RevF, RevD and older

v0.4 LCD and SD card support works correctly, fixed other bugs

v0.3 Software Fan PWM disabled - caused major decrease in print quality

v0.2 Software FAN PWM enabled to silence squeaky fans

More Firmware for other models is avalible below - You will need to compile Marlin 1.1.8

http://www.xilka.com/printrbot/marlin/1.1.8/20171227a/

Marlin 1.1.9 first time bed leveling guide - after flashing

Printrbot Play 0.2mm layer height Cura 3.5.1

This isn’t your grandma’s 3D printer, please make sure your inductive probe is adjusted properly

- This firmware should be universal for any printrbot, just choose heated bed firmware if you have that option.

- You will need to update the steps/mm for your machine Settings for your Printer Smalls, Simple, Play Plus

- Depending on the model of your printer you will need to adjust the Stepper current

Set Stepper Current

M909

READ: echo:Stepper current values in % (Amps):

Stepper current values in % (Amps):

READ: echo: X:60.00 (16581.82) Y:65.00 (36581.82) Z:60.00 (16581.82) E:65.00 (36581.82)

X:60.00 (16581.82) Y:65.00 (36581.82) Z:60.00 (16581.82) E:65.00 (36581.82)

Example: M907 X60 sets the X-axis motor current to 60% of max possible

M909 Read Motor current Values

M907 Set Current Value

M910 Store Stepper Current Values

Linear Advance is enabled by default

Retraction distance should be limited to 0.7mm

Default value is K0.08 Be sure to calibrate your extruder before a

This can be adjusted while printing

M900 K0.08 ;set k value

M500 ;save

Play with MK8 style extruder Use a K0.05

-

Calibrate your extruder steps/mm before K-factor Extruder Calibration

- Please calibrate your K-factor and share results,

- Each material and color has its own properties for best results calibrate for each material you use. Add the K value to your start gCode for each material Linear Advance gcode Geneartor

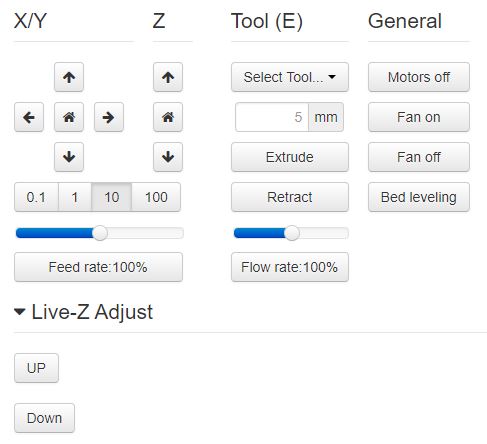

Babystepping Z-Offset adjustment while printing

- M290 and LCD menu item to move the z axes by tiny increments without changing the current position values. This feature is used primarily to adjust the Z axis in the first layer of a print in real-time.

- Replaces the need to set the Z-offset multiple times using M212 before printing.

- Easily adjust your offset by adding custom buttons to octoprint using Custom Control Editor Plugin

Z-Offset (the old way M212)

M851 Z-1.95 ;this is the default value

M500 ;save

LCD & SD Card

LCD Support for Reprap_Discount_LCD, Ultipanel and Ultra_lcd

SD Card reader integrated in LCD controller should work

Start gCode

M82 ;absolute extrusion mode

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

G28 ;move X/Y to min endstops

G29 ;run auto bed leveling

G92 E0 ;zero the extruded length

G1 X0 Y0 Z.2 F7000 ;move to front corner and lower

G1 X35 Z.2 E35 F800 ;purge 35mm of filament

G92 E0 ;zero the extruded length again

G1 F9000

;Put printing message on LCD screen

M117 Printing...

Useful gCode

M420 S1 ;loads previous bed leveling matrix

M900 K0 ;disables Linear Advance

M900 K0.5 ;Set linear advance K-value

M290 Z0.02 ;babystep move up 0.02mm on the Z axis

M115 Feature support list

M43 Debug Pins

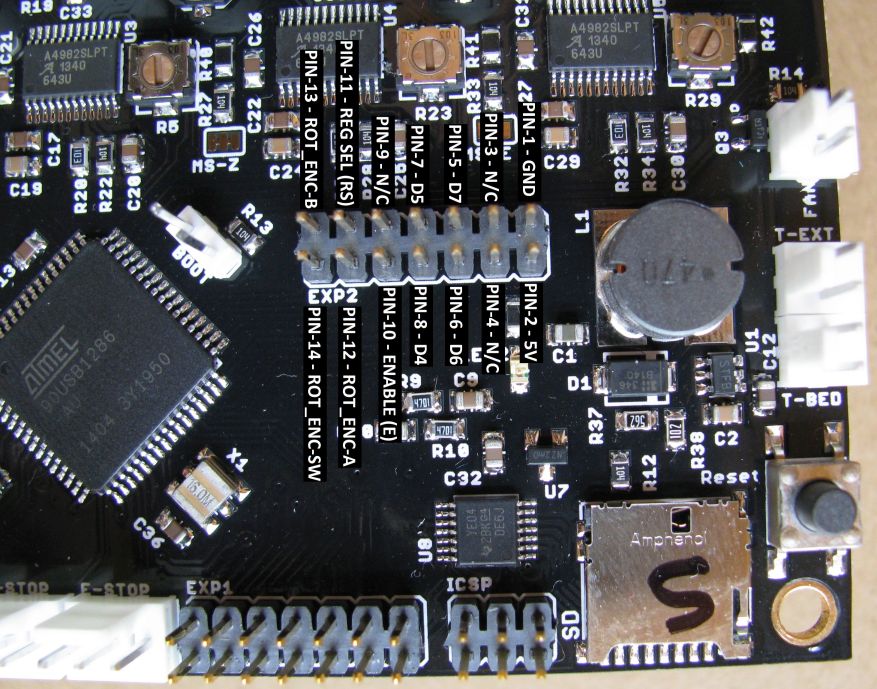

Expansion Header pinout diagrams

Neopixel Pins

EXP2 Pinout

Using Printrboard without an LCD - all commands available LCD Menu gcode equivalent

##### Build Using PlatformIO or Marlin-Config GUI editor I find Marlin GUI editor can be very laggy so instead I prefer to access it through Chrome

http://localhost:3000

Marlin-config GUI The printrboard only has 128kb of program memory this build of marlin 1.1.9 as configured currently occupies 99.1%

##### Flash using ATMEL FLIP Before Flashing check your eprom and save your steps/mm and machine size After Flashing Make sure to set EPROM to defaults using M502 then M500 to save ATMEL FLIP Download

##### Guide Firmware Loading Guide

##### Programming firmware without a bootloader Caution! Don’t even mess with this if you don’t know what you’re doing! DFU bootloader uses 6k of program memory, inorder to get more features in limited space I choose to program firmware using a USBtinyISP More information

avrdude -c usbtiny -p at90usb1286 -U flash:w:FirmwareHexFileNameHere.hex:i